Karl DEUTSCH FLUXA® Inspection Media for magnetic particle testing

The premium choice for testing under UV-light

FLUXA® Ready Concentrates: Easiest way of preparation.

You only need water to obtain the ready-to-use suspension. The contained additives are sufficient for nearly all cases.

FLUXA® Medium Concentrates: Optimum compromise between price and preparation procedure

The medium concentrates already contain wetting agent and a certain amount of rust inhibitor which will be sufficient for most testing tasks. In that case, only water must be added.

FLUXA® High Concentrates: Cheapest types of concentrates.

Even for these concentrates the often troublesome mixture of powder in water is not required. However, rust inhibitor and wetting agent must be added.

FLUXA® Powder (wet process): Universally applicable and cheapest possibility.

FLUXA® Powders designed for the wet process are based on iron oxides. Thus, rust and quick settling are avoided.

FLUXA® – Ready-to-use

Ideally suitable for manual testing of single parts or on-site.

New: FLUXA® HRS (Art. No. 9306.9)

The water-based inspection medium is VOC-free and complies with DIN EN ISO 9934-2, SAE AMS 3044 as well as ASTM 1444. Ready-to-use and environmentally friendly it is available in handy aerosol can. A Technical Data Sheet and the Safety Data Sheet can be found here. We gladly provide samples for your own tests free of charge (send an e-mail to info@karldeutsch.de or use our contact form).

Our current FLUXA® leaflet provides an excellent overview of the diversity of our magnetic particle inspection media and assists you to find out which FLUXA® testing agent fits best to your needs. Please download it from our downloads page or click on the thumbnail below.

DEUTROFLUX® Powder (dry process) article nos. 9030 – 9033:

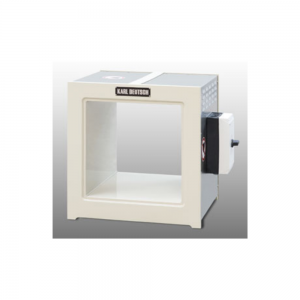

These powders are used for the dry process, e.g. to meet certain U.S. prescriptions or for vortex chamber testing. The powder is applied on the specimen without a carrier medium, i.e. blown over the workpiece, or the residually magnetized workpiece is dipped into the powder bath of the vortex chamber. Suitably fine and coarse qualities should be mixed for these purposes.

Standards and Specifications for each FLUXA® testing agent are described in detail within the appropriate Technical Information Sheets and Material Safety Data Sheets (MSDS) which can be obtained directly from our download section.

For more information visit Karl Deutsch website.

Jus taip pat gali dominti

Karl DEUTSCH UV LED Large Area Lamp 3846 for the fluorescent penetrant and magnetic particle testing

The multifunctional UV LED large area lamps are ideally suited…

IšsamiauKarl DEUTSCH UV LED Combi Hand Lamp 3815

The portable hand lamp for mains and battery operation A…

IšsamiauKarl DEUTSCH Reference Magnet and Zero Field Chamber, Accessory for the field strength meter deutrometer 3873

The application range Reference magnet and zero field chamber are…

IšsamiauKarl DEUTSCH Magnetic Particles Testing DEUTROPULS Hand Yokes

Mobile Crack detection: Safe and reliable The DEUTROPULS Hand Yoke…

IšsamiauKarl DEUTSCH Magnetic Particle Test Units DEUTROPULS

Portable high current generators In different power classes a mobile…

IšsamiauKarl DEUTSCH Field Strength Meter DEUTROMETER 3873

Convenient and practice-oriented measurement of field strength The DEUTROMETER 3873…

IšsamiauKarl DEUTSCH ESV Demagnetizing Coils, Accessory for Magnetic Particle Crack Detection

For the demagnetization of magnetized parts ESV coils are used…

Išsamiau